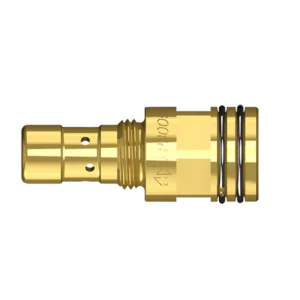

XP8 Contact Tip 1/16” – 1.6mm (XP8-320A-450W) – Packet of 10

Premium XP8 1/16″ (1.6mm) contact tips for MIG welding torches. Ensures smooth wire feeding, precise arc control, and long-lasting performance. Ideal for professional welding tasks.

- Estimated Delivery : Up to 4 business days

Upgrade your welding setup with the XP8 Contact Tip 1/16″ 1.6mm – 10 Pack (XP8-320A-450W) – Packet of 10. Designed for seamless performance, these contact tips provide consistent wire feeding, precise arc control, and enhanced durability. Perfect for both professional welders and DIY enthusiasts, they ensure every MIG weld is accurate and reliable. Crafted from high-quality copper, these tips resist wear and reduce downtime, allowing for continuous operation without frequent replacements. Compatible with XP8 series MIG torches (320A–450W), they are essential for achieving clean, professional welds across a variety of metal types. With easy installation and excellent conductivity, these contact tips enhance welding efficiency and reduce spatter. Pack of 10 ensures you always have replacements on hand, keeping your workflow smooth and uninterrupted.

Key Features

Precision-engineered 1/16″ (1.6mm) tip for smooth wire feed.

Compatible with XP8 MIG torches (320A–450W).

High-quality copper construction for durability.

Reduces welding spatter for cleaner results.

Easy to replace and maintain during welding tasks.

Specifications

Diameter: 1/16” (1.6mm)

Material: High-grade copper

Compatibility: XP8-320A/450W MIG torches

Pack size: 10 contact tips

Weight: Approx. 0.15 kg per packet

Benefits & Uses

Ensures precise and consistent MIG welding performance.

Reduces downtime due to wear-resistant copper material.

Ideal for professional workshops and industrial projects.

Improves arc stability and wire feed reliability.

Versatile for use on steel, stainless steel, and aluminum welding.