XP8 5mtr Steel Liner for 0.6 -0.9mm Wire (200A/300A)

XP8 5m Steel Liner for 0.6–0.9mm wire, compatible with 200A/300A air-cooled MIG torches. Smooth wire feed and durable performance.

- Estimated Delivery : Up to 4 business days

Upgrade your welding performance with the XP8 5m Steel Liner for 0.6–0.9mm Wire (200A/300A)—a premium-quality liner engineered for smooth, consistent, and trouble-free wire feeding. Designed for MIG torches in the XP8 series, this steel liner delivers exceptional durability, reduced friction, and higher feeding accuracy, even in demanding industrial workflows. Whether you’re working in fabrication, automotive repair, engineering workshops, or heavy-duty welding environments, this liner ensures stable performance with minimal wear.

Built for professionals who demand reliability, the XP8 Steel Liner improves wire flow, reduces burn-back, and enhances overall weld quality. Its 5-meter length provides extended reach, making it ideal for large workpieces and workshop flexibility. With compatibility for 200A and 300A MIG torches, it’s a perfect replacement part for maintaining optimal torch efficiency. Engineered with precision and crafted from high-grade steel, this MIG liner reduces downtime, improves feed stability, and increases the lifespan of your torch consumables—helping you work faster, cleaner, and more efficiently.

Key Features Of XP8 5m Steel Liner 0.6–0.9mm

High carbon steel construction for durability

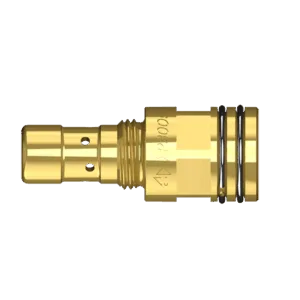

Tapered seat O-ring seals for secure fitting

Compatible with polyamide drive roll systems

Ensures smooth, consistent wire feed

Suitable for XP8 200A and 300A air-cooled MIG torches

Specifications

Length: 5 Metre

Wire Size: 0.6mm – 0.9mm

Material: High Carbon Steel

Compatibility: XP8 200A / 300A air-cooled torches

BENEFITS & USES

Enhances wire feeding performance for smoother, cleaner welds.

Extends the lifespan of your MIG torch by reducing strain and friction.

Ideal for fabrication shops, automotive welding, and industrial applications.

Reduces downtime and maintenance by preventing feeding issues.

Improves overall welding efficiency and operator productivity.