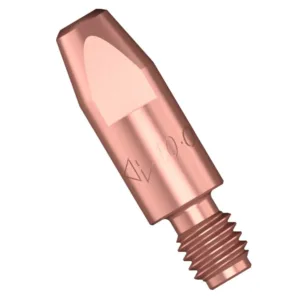

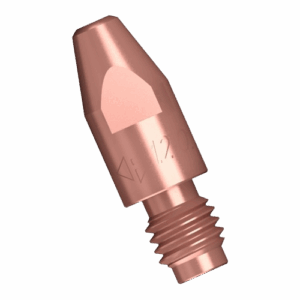

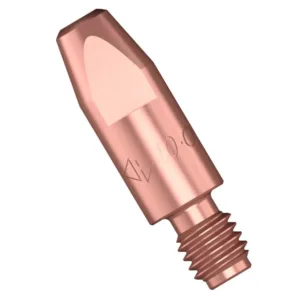

BINZEL Contact Tip 1.2mm (250A–360A) M6 Thread (10 Pack)

The BINZEL Contact Tip 1.2mm M6 (10 Pack) delivers exceptional precision, long life, and reliable wire feeding for 250A–360A MIG welding. Designed for heavy-duty industrial use, these heat-resistant tips ensure clean, stable arc performance. Perfect for welders requiring durable and consistent results.

- Estimated Delivery : Up to 4 business days

The BINZEL 1.2mm Tip – 10 Pack is engineered for welders who demand precision, durability, and consistent wire feeding in every weld. Designed for MIG welding applications, these high-performance contact tips ensure stable arc control, minimal spatter, and smooth current transfer, helping you achieve cleaner, more accurate welds. Built from wear-resistant copper alloy, each tip maintains its shape under heat, offering long service life even in demanding industrial environments.

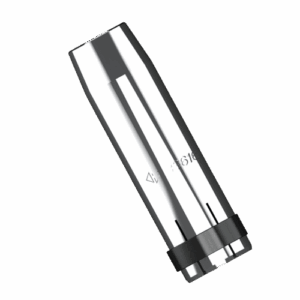

With a precise 1.2mm bore size, this BINZEL tip supports high-amperage welding, making it ideal for fabrication shops, automotive welding, heavy steel work, and maintenance tasks. The M6 thread ensures universal compatibility with a wide range of BINZEL-style MIG torches used across Ireland and Europe. Whether you’re handling stainless steel, mild steel, or flux-cored wire, these tips deliver consistent performance for professional-grade results. Perfect for welders who value reliability, efficiency, and reduced downtime, the BINZEL Contact Tip 10-pack offers excellent value, keeping your welding workflow uninterrupted and productive.

Key Features Of BINZEL 1.2mm Tip – 10 Pack

Compatible with BINZEL 250A–360A MIG torches

1.2mm bore for accurate wire feed

M6 thread ensures secure fitting

Copper construction for high conductivity and durability

Supplied in a 10-pack for convenience

Specifications

Type: Contact Tip

Wire Size: 1.2mm

Thread Size: M6

Amperage Range: 250A–360A

Material: Copper

Pack Quantity: 10

Compatibility: BINZEL-style MIG torches

Benefits & Uses

Enhances wire feeding accuracy for cleaner welds.

Withstands high heat during long welding cycles.

Reduces burnback and maintains consistent arc control.

Ideal for fabrication workshops, automotive, and steel work.

Increases productivity by reducing frequent tip replacements.